Table of Contents

Introduction

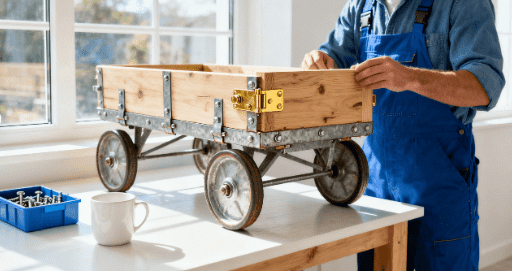

The classic wood wagon is far more than just a nostalgic toy; it remains an incredibly practical and durable asset for countless tasks, ranging from complex landscaping projects to simple, enjoyable recreational use. Its traditional appeal is matched by its inherent strength, provided you choose the right model. However, selecting the perfect wood wagon requires a methodical approach that goes beyond aesthetics. This comprehensive guide outlines six proven strategies—encompassing material science, engineering robustness, and consumer protection—to ensure that your investment results in a high-quality, long-lasting wood wagon that meets every demand you place upon it. We aim to equip you with the knowledge necessary to navigate the market and secure the best possible piece of equipment.

Understanding Your Needs Before Buying a Wood Wagon

Before embarking on the search for the perfect model, the foundational step is rigorous self-assessment: what will the primary function of your wood wagon be? A unit intended for occasionally moving children during a parade requires vastly different specifications than one slated for daily hauling of bricks, wet soil, or heavy firewood. Determining whether the use is light recreational, moderate gardening, or heavy-duty construction will critically inform your decisions regarding material grade, capacity, and wheel type.

Assessing Durability: The Best Wood Wagon Materials (Way 1)

The longevity and resilience of any wood wagon are intrinsically linked to the materials used in its construction. Avoid models made from inexpensive, fast-growing softwoods like untreated pine, which are highly susceptible to moisture absorption, warping, and fungal rot. Instead, prioritize hardwoods such as oak, known for its exceptional density and natural resistance to decay, or high-grade marine plywood, which is engineered specifically for outdoor resilience.

Beyond the core wood, examine the protective treatments applied. A high-quality wood wagon should feature a robust sealant, such as multiple coats of polyurethane, epoxy, or a specific outdoor varnish. These finishes create a waterproof barrier, shielding the wood from harsh UV rays and precipitation. Moreover, proper finishing ensures that the wood wagon maintains its structural integrity and aesthetic appeal over many years of exposure to the elements. Durability is not just about the wood itself but how well that wood is protected against environmental stress.

Checking Weight Capacity for Any Wood Wagon Task (Way 2)

Load bearing capacity is arguably the most critical engineering specification. Manufacturers must clearly specify the maximum distributed load their wood wagon can safely handle. For safety and equipment lifespan, it is a cardinal rule to select a wood wagon with a weight rating significantly higher—ideally 25% to 50% higher—than the heaviest load you realistically anticipate hauling.

This safety margin prevents stress fractures and premature failure of critical components. For heavy-duty applications, the strength of the bed must be supported by equally robust undercarriage components. Look specifically for full-length steel axles, reinforced chassis bracing, and strong joint connections that distribute stress evenly across the bed of the wood wagon. Overloading a unit, even once, can permanently compromise the alignment and structural integrity of the frame, leading to ongoing issues.

3 Crucial Steps for Inspecting a Wood Wagon

The next three steps represent crucial physical checks that transition the focus from materials science to mechanical execution.

The Importance of Wheel Type for a Wood Wagon (Way 3)

The type of wheel dictates the ease of movement and the capability of the wood wagon across varied terrain. Pneumatic (air-filled) tires are superior for rough, uneven surfaces like gravel paths, grass, or dirt tracks. The air cushion provides excellent shock absorption, reducing impact on the load and making the wood wagon much easier to pull over obstacles. However, pneumatic tires require occasional checking and inflation and are susceptible to punctures.

Conversely, solid rubber or plastic wheels are maintenance-free and cannot puncture. They perform exceptionally well on smooth, paved surfaces (driveways, sidewalks) but transfer more vibration and require more effort to pull on soft ground. When inspecting the wheels, also check the quality of the bearings; sealed, high-quality bearings ensure smooth rotation and long-term performance, regardless of the wheel type you choose for your wood wagon.

Vetting the Hardware and Assembly (Way 4)

The hardware holding the wood wagon together must withstand continuous stress, vibration, and exposure to moisture. Inferior hardware quickly rusts, loosens, and eventually fails. Prioritize models that utilize galvanized, zinc-plated, or, optimally, stainless steel bolts, nuts, and washers. These materials offer superior resistance to corrosion and rust, a common weak point for outdoor equipment.

Beyond the visible fasteners, meticulously inspect the critical connection points, particularly the steering mechanism and the handle attachment. The handle should attach to the front axle assembly with a secure pivot pin and robust bracketry. Any sign of excessive play or wobble in the handle joint is a red flag indicating weak assembly or materials that will quickly fail under load. High manufacturing standards include recessed hardware where appropriate, minimizing snagging and creating a cleaner look for the wood wagon.

Evaluating Manufacturer Warranties and Returns (Way 5)

A comprehensive warranty is the manufacturer’s pledge of quality and your protection against unexpected defects. Look for warranties that cover not only the wood components (against warping or rot) but also mechanical failure of the hardware and chassis for a minimum of one to three years.

Generous return and replacement policies are strong indicators of confidence in the wood wagon’s durability. A reputable seller should clearly define what constitutes a defect and ensure replacement parts (like wheels or handles) are readily available for purchase years down the line. A strong warranty significantly mitigates the risk associated with a higher initial investment.

| Wood Wagon Feature | Best Choice for Heavy Hauling | Best Choice for Light/Recreational Use | Impact on Performance |

| Wood Type | Oak or Marine-Grade Plywood | Pine or Cedar (Treated) | Determines structural rigidity and rot resistance |

| Wheel Type | Pneumatic (Air-Filled) | Solid Rubber | Influences ease of pulling and shock absorption |

| Axle Material | Steel (Thick Diameter) | Standard Metal/Alloy | Affects maximum load bearing capacity |

| Hardware | Stainless Steel/Galvanized | Standard Screws/Bolts | Crucial for resistance to rust and loosening |

| Key Advantage | High Load Bearing, Durability, Terrain Versatility | Lighter Weight, Lower Maintenance, Cost Savings | Defines the intended purpose and lifespan |

Finding the Right Price and Value (Way 6)

The final strategy in purchasing the best wood wagon is moving beyond the sticker price and calculating true value. The principle of Total Cost of Ownership (TCO) applies here: a cheap wood wagon that needs constant repair, replacement parts, or premature discarding ultimately costs more than a higher-priced, high-quality unit.

Analyze the market price in relation to the features identified in Ways 1 through 5. If a wood wagon incorporates premium features—such as stainless steel hardware, thick oak construction, and pneumatic tires—the corresponding higher price is usually justified by its extended lifespan and superior performance. Seek out reputable dealers specializing in durable outdoor equipment, rather than general merchandise stores, as they often stock models built to commercial or professional standards. Never let minor initial savings compromise essential durability features; longevity should always be the paramount factor when assessing the value of a wood wagon.

Conclusion

The pursuit of the best wood wagon is a journey best taken with an informed, systematic approach. By diligently applying these six proven strategies—defining precise usage requirements, scrutinizing material quality and protection, verifying stated load capacity, selecting the appropriate wheels, demanding superior hardware, and prioritizing long-term value over short-term savings—you ensure that your purchase is a reliable, durable asset. A thoughtfully selected wood wagon will not only fulfill its functional purpose but will also stand as a lasting piece of equipment for generations.

FAQ

How do I maintain my wood wagon for long-term use?

The key to maximizing the life of your wood wagon is prevention. Storage is paramount; always keep the wood wagon in a dry, covered environment, such as a garage or shed, to prevent exposure to cycles of rain and sun, which cause wood to expand and contract. Annually, inspect all bolts and nuts, tightening any that have loosened due to vibration. If the protective sealant appears worn or chipped, lightly sand the affected area and reapply an exterior-grade protective finish to maintain the moisture barrier and prevent rot and fading.

Can a wood wagon be used in snowy or wet conditions?

While a well-constructed and treated wood wagon can withstand incidental use in wet conditions, continuous exposure is detrimental. If used in snow, be extremely vigilant about cleaning the wood wagon afterward, as road salts and de-icing chemicals are highly corrosive to metal hardware and can degrade the wood sealant quickly. Dry the unit thoroughly after every use in moisture, and consider applying a thin layer of grease to exposed metal axles and hardware during the winter months for extra protection.

What are the typical dimensions or sizes available for a commercial-grade wood wagon?

Commercial or heavy-duty wood wagons often come in bed sizes ranging from 20 inches wide by 36 inches long up to 30 inches wide by 48 inches long. These larger dimensions accommodate bulky items like construction materials or multiple bags of soil. For recreational or light home use, smaller models (around 18 x 30 inches) are common, offering easier maneuverability and lighter storage profiles. Always confirm the interior dimensions of the bed versus the overall external dimensions when comparing models.

Keep the Conversation Going!

Loved this article? Join our community for more industry insights, real-time discussions, and exclusive updates. Find me here:

→ Facebook: Qingdao Kinkayo Industry and Trade Co., Ltd.

→ YouTube: Kinkayo Industry and Trade

Let’s explore innovation together—connect now!